V-8D built-in high speed vertical machining center

- Model

- V-8D

Item specifics

- Numerical control

- FANUC/MITSUBISHI

- Control method

- Semi-closed loop control

- Three axes

- linear guideway

- Brand

- SINO

- Spindle

- built-in spindle

Review

Description

Product Introduction

V-8D

High Speed Spindle Built-in Vertical Machining Center

- 40

TAPER

- 3

AXIS

- 24000

RPM

- 24

TOOL CAPACITY

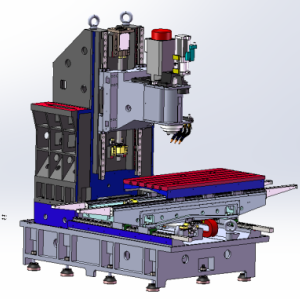

V-8D Built-in Spindle High Speed Vertical Machining Center

V-8D series is the top selling machine series due to its high speed but high power intergrated machining performance on rigidity and accuracy. It is designed by SINO independent R&D department , which improves production effiencey and machining quality greatly.

Product Detailed Parameters

Machine Model : V-8D

| Table | Value | Unit |

|---|---|---|

| working size | 1000 x 500 | mm |

| Max. load capacity | 500 | kg |

| Travel | Value | Unit |

|---|---|---|

| X travel | 850 | mm |

| Y travel | 500 | mm |

| Z travel | 550 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle nose taper | BT40 | |

| Spindle speed (direct driven) | 16000 /20000/24000 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 48/48/32 | m/min |

| ATC | Value | Unit |

|---|---|---|

| Number of tools | 24 | T |

Product Details Map

Machine structure :

The contact ratio between spindle case and column increased to ensure spindle rigidity.

1100mm wide machine body span and optimum supporting design can meet with fast feed of X and Y axis.

Big size of “pyramid” column and with closed inner cavity to ensure low center but high rigidity support of Z axis.

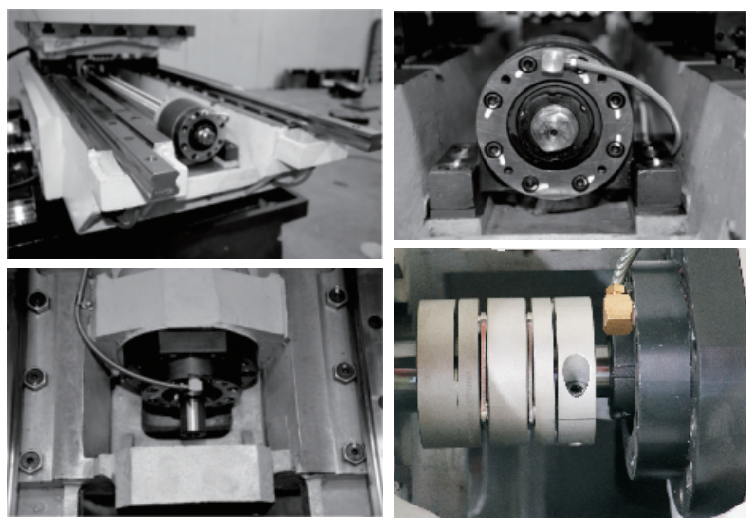

Preloaded and double anchored ball screw :

Servo motor directly coupled ball screw.

All the ball screws, linear guideway, bearings are well lubricated in time and ration.

Y/Z axis adopt 45mm linear guideway while X axis adopts 35mm which make the rapid feed speed reach 48/48/32m/min.

In order to eliminate thermal growth and increase accuracy, all axes are driven by high precision double anchored ballscrews. Also 5 rank high precision angular contacted bearing installed aside the ball screw and make pre-tension.

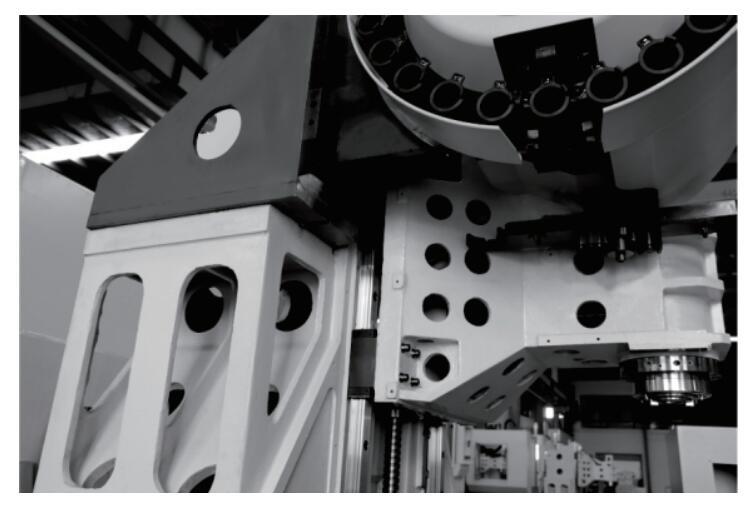

Shoulder carrying tool magazine :

Shoulder carrying tool magazine can ensure Z axis geometric accuracy and perfect stability, rigidity and the minimum deformation when column loaded with tool magazine weight.

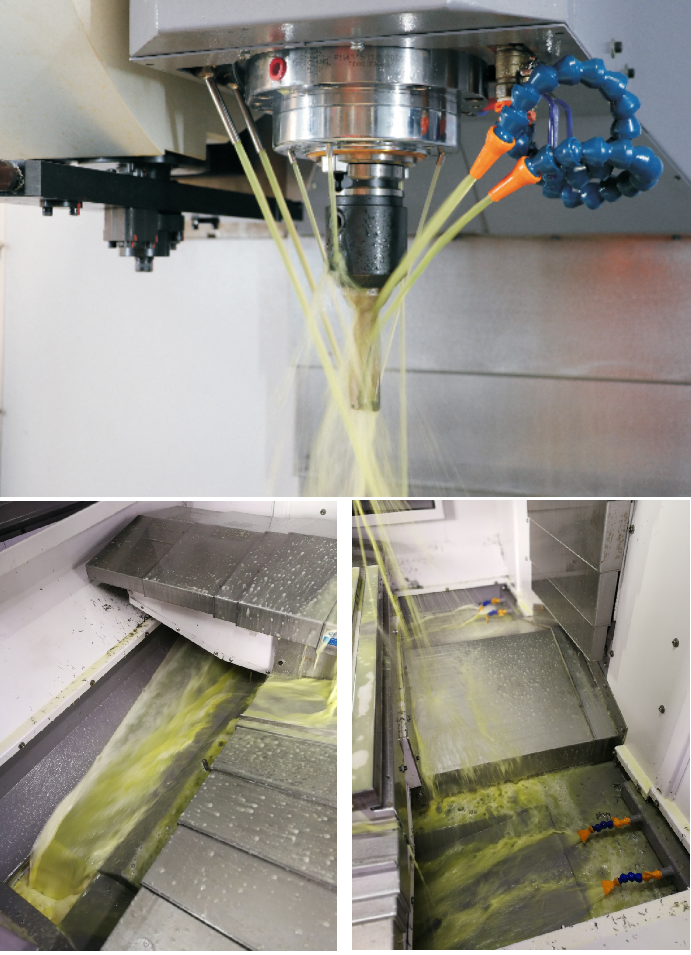

Large flow coolant fluid :

Labyrinth style cover design to protect machine from scraps and cutting fluid.

Standard equipped with inner side flushing system to remove scraps efficiently.