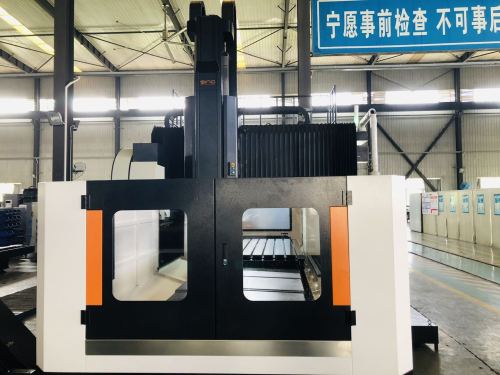

High rigidity heavy cutting best double column machining center price for SP1016

- Model

- SP1016

Item specifics

- CNCcontrol

- FANUC/SIEMENS/MITSUBISHI

- Control method

- Semi-closed loop control

- 3 axes

- X/Y roller linear guideway Z box guideway

- Brand

- SINO

Review

Description

Product Introduction

SP-1016

High Rigidity Heavy Cutting Double Column Machining Center

- 50

TAPER

- 3

AXIS

- 7k

RPM

- 24

TOOL CAPACITY

SP1016 High Rigidity Heavy Cutting Double Column Machining Center

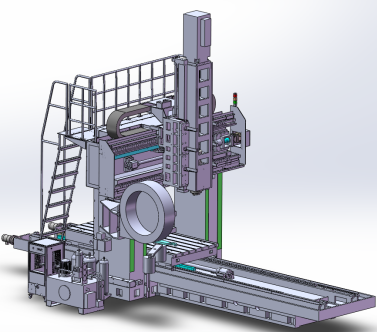

For this series column and beam fixed best double column machining center, we adopt international dynamic rigidity design idea and optimize the moving parts on the basic of high rigidity,structure symmetry,high stability of traditional double column machining center. This series machines have the characteristic of high torque and fast feedback, which can meet the demand of auto,mould,aviation,military industrial and other mechanical machining field. This series machines are mainly made of base,worktable,columns,beam,saddle,hydraulic system,lubrication system,cooling and filtering system,chip device, CNC system and other parts.

Product Detailed Parameters

Machine Model : SP1016

| Table | Value | Unit |

|---|---|---|

| working size | 1600 x 1000 | mm |

| Max. load capacity | 3.5 | T |

| Travel | Value | Unit |

|---|---|---|

| X travel | 1650 | mm |

| Y travel | 1100+160 | mm |

| Z travel | 600 | mm |

| Distance between two columns | 1250 | mm |

| Distance from spindle nose to worktable surface | 160-760 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle nose taper | BT50 | |

| Spindle speed (pulley) | 7000 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 20/20/12 | m/min |

| ATC | Value | Unit |

|---|---|---|

| Number of tools | 24 | T |

Product Details Map

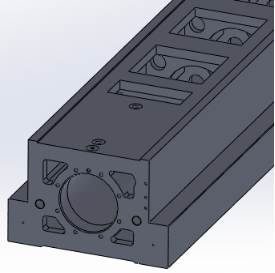

Spindle:

For 10 series, it is with belt type as designed to replace large size VMC with higher rigidity and stability but competitive price;

Equipped with tool cylinder for pneumatic tool clamping and unclamping;

Z axis motor is designed to balance Z axis weight including spindle box, spindle and so on

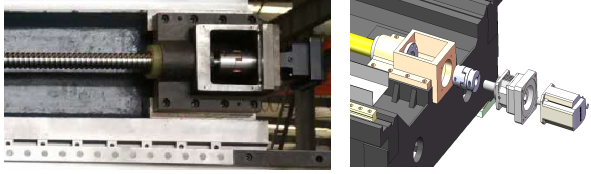

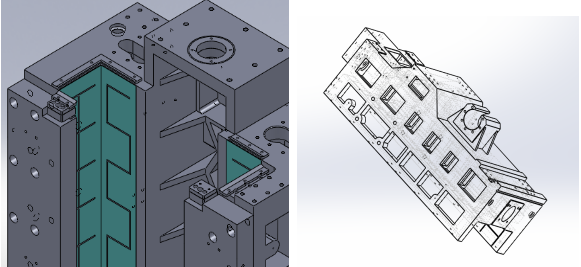

3 axes driving :

The ball screws are directly coupled to the servo motor. It will express mostly motor performance and improve machine accuracy and efficiency;

10 years free service reducer STOBER in X \Z axes (Germany brand)

Spindle box :

With large cross section design, it improve spindle box rigidity by 20% compared with other competitors;

SINO spindle box thickness is 345mm, usually competitors’ is just 60mm

Saddle :

To improve saddle rigidity and anti-shock, Z axis is made of box guideway with plastic which is manually scraped well;

One piece of screw nut seat and saddle to improve machine accuracy

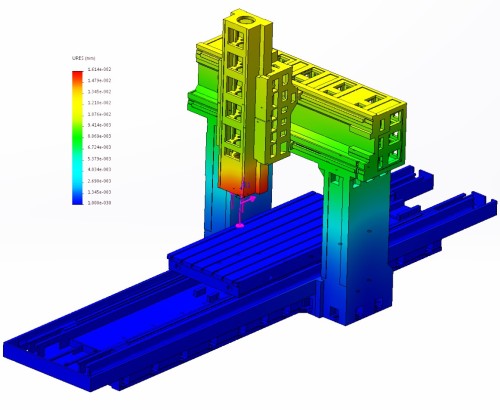

Beam

Ladder designed beam assured spindle case gravity backward;

Reasonable distance between guideway to spindle center by FEA

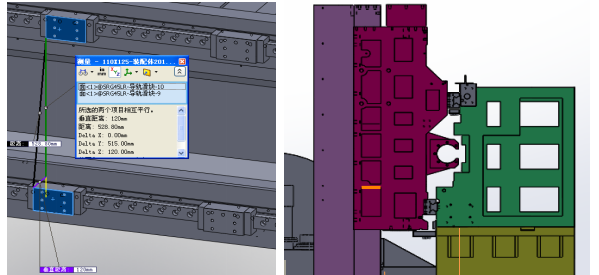

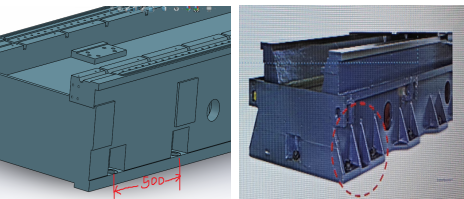

Base :

Foundation hole keep in vertical line with linear guideway which assure a better loading support;

If machine is installed by two holes, one fixing hole and one adjusting hole, the machine base is easily deformed due to unequal force;

Trapezoid foundation hole ensure machine stability;

500mm distance between two holes keep reasonable equal force

Imported configuration