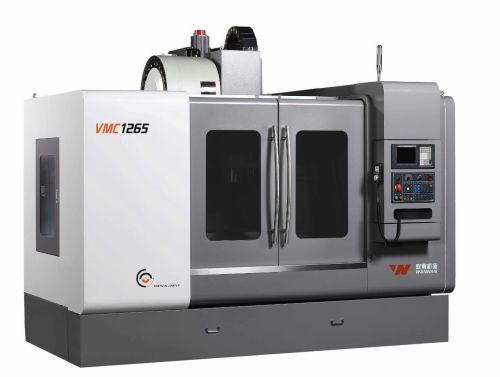

VMC1265 metal cutting machining center for sale

- Model

- VMC1265

Item specifics

- Numerical control

- FANUC/SIEMENS/MITSUBISHI

- Control method

- Semi-closed loop control

- Three axis

- box guideway

Review

Description

Product Introduction

VMC1265

Heavy cutting high rigidity machining center

- 50

TAPER

- 3

AXIS

- 6K

RPM

- 24

TOOL CAPACITY

VMC1265 High Rigidity Heavy Cutting Vertical Machining Center

This series vertical machining center adopts the moving structure of cross sliding table and sliding guide,which is mainly applied in processing of middle and small scale complicated parts.Apply the computeraided engineering(CAE)system to finish the optimized structure design and enhance the reliability of machine tool,and the finite element method(FEM)to take the scientific analysis and optimization of design structure, which can guarantee the rigidity and stability of the whole machine structure.

Product Detailed Parameters

Machine Model : VMC1265

| Table | Value | Unit |

|---|---|---|

| working size | 1400 x 650 | mm |

| Max. load capacity | 1200 | kg |

| Travel | Value | Unit |

|---|---|---|

| X travel | 1200 | mm |

| Y travel | 670 | mm |

| Z travel | 665 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle nose taper | BT50 | |

| Spindle speed (pulley) | 6000 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 15/15/12 | m/min |

| ATC | Value | Unit |

|---|---|---|

| Number of tools | 24 | T |

Product Details Map

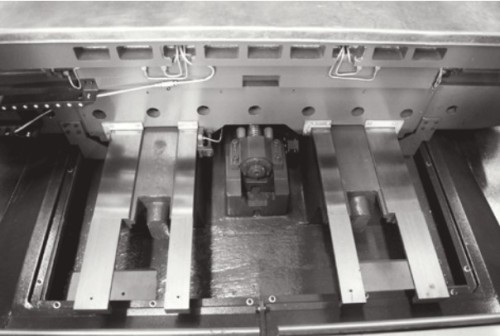

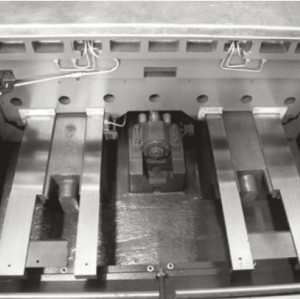

Machine Structure:

X, Y, Z three-axis adopts ultra-wide guide rails, which have excellent rigidity, vibration absorption (suppressing vibration generated when cutting tools) and damping (preventing vibration when the guide system is started or stopped)

Suitable for machine tools with heavy cutting loading

Y axes are supported by 4 guide rails, which has stronger carrying capacity

Spindle :

Taiwan brand BT50-150mm spindle, standard is belt drive 8000rpm. Optional is 10000rpm.

Ultralight spindle headstock and Z axis with counter balance block

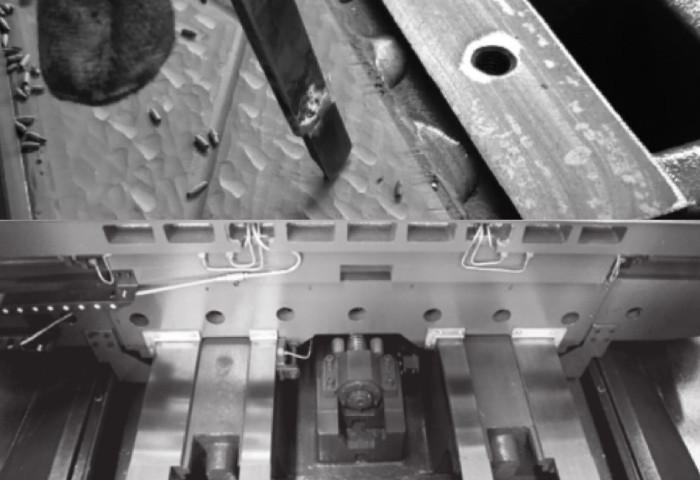

Manual Scrape :

Manual scraping is used on the main joint surface to ensure effective contact area and improve the accuracy;

It is also beter for lubrication as oil slick will formed after manual scrape;

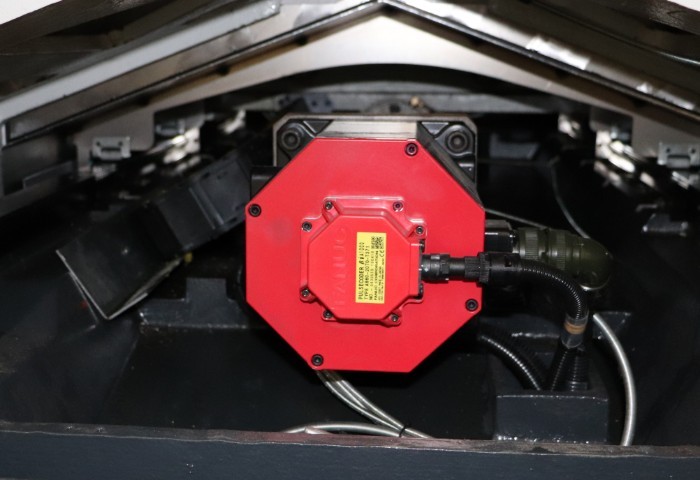

Axes Driving :

The 3 axes servo motors are directly connected to the high-precision ball screw via a gapless elastic coupling to ensure transmission accuracy.

All servo motors are equipped with absolute encoders to increase efficiency and reliability.

The three axis screw is pre-stretched to eliminate the influence of screw temperature rise on machining accuracy

Physical Picture