X6132B Horizontal Keen-Type Milling machine

- Model

- X6132B

Item specifics

- Brand

- SINO

- Three axes

- Box guideway

Review

Description

Product Introduction

X6132B

High Rigidity Horizontal Keen-type Milling machine

- 7:24 No.50

SPINDLE HOLE TAPER

- 3

AXIS

- 30-1500

RPM

- 18

SPINDLE SPEED STEPS

X6132B High Rigidity Horizontal Keen-type Milling machine

X6132B horizontal knee-type milling machine is a general purpose machine which can be used in wide range. Mounted with face, cylindrical, side, bevel and formed milling cutters, the machine is suitable to process flat, inclined surface, slots and gears on miscellaneous work pieces.

Equipped with optional accessories, such rotary table and dividing head, machine can be applicable to versatile processing. It is an ideal machine tool for machining process, maintenance, instrument, die and moulds.

Product Detailed Parameters

Machine Model : X6132B

| Table | Value | Unit |

|---|---|---|

| working size | 1320 x320 | mm |

| Max. load capacity | 500 | kg |

| Travel | Value | Unit |

|---|---|---|

| longitudinal travel (manual / power) X | 800/780 | mm |

| cross travel (manual / power) Y | 300/280 | mm |

| Vertical travel ( manual / power) Z | 410/400 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle hole taper | 7:24 No.50 | |

| Spindle speed | 30-1500 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 2250/2250/844 | mm/min |

| Moter power | Value | Unit |

|---|---|---|

| Main motor power | 7.5 | Kw |

Product Details Map

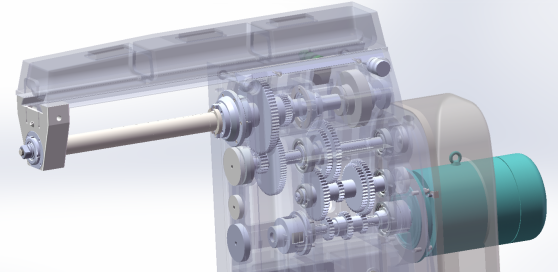

Transmission:

Spindle and feed are in hardened gear transmission with 18 grades speed ranges.

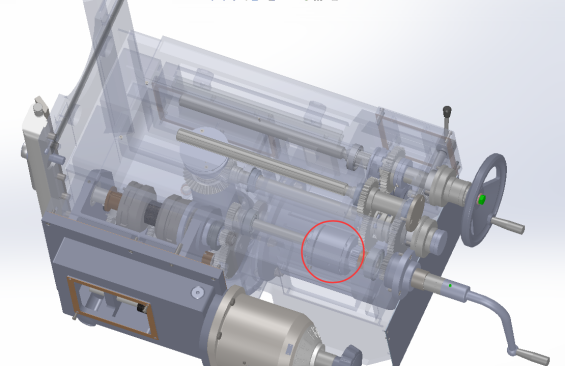

Over-load protection clutch:

Over-load protection clutch in spindle and feed transmission. If machine worked over-load, it will stop automatically.

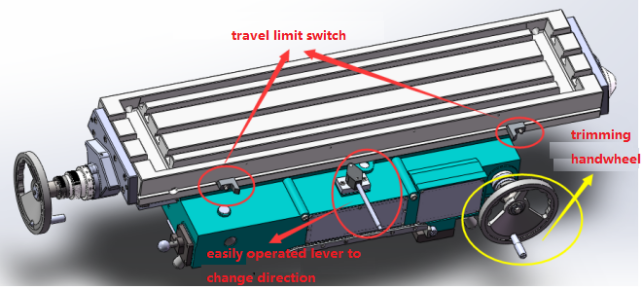

Auto-stop and protective device :

Auto-stop and protective device on feed movement which let operator can change direction easily.

Equipped with trimming handwheel, machine can work in small size processing range.

-

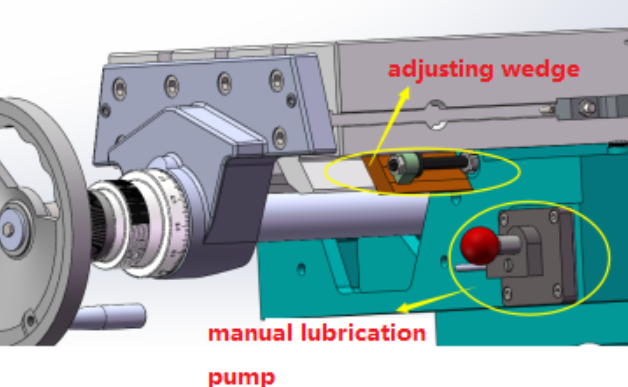

Adjusting wedge:

Adjusting wedge in each guideway to ensure accuracy in long time.

With extra manual lubrication pump, every part can be lubricated sufficiently.

Arm :

Arm can be moved back and install vertical milling head.

-

Worktable:

Worktable can be rotated by ±45°